About SimIS' 3D Printing & Rapid Prototyping Capability

When ordering FDM 3D printing through SimIS, you get the benefits of Industrial additive manufacturing without the costs associated with buying and maintaining entire machines. You also get the agility and responsiveness of working with a small business partner. Combined with our Instant Quoting Engine, our online 3D printing service can turn around your FDM parts in as little as 1 day.

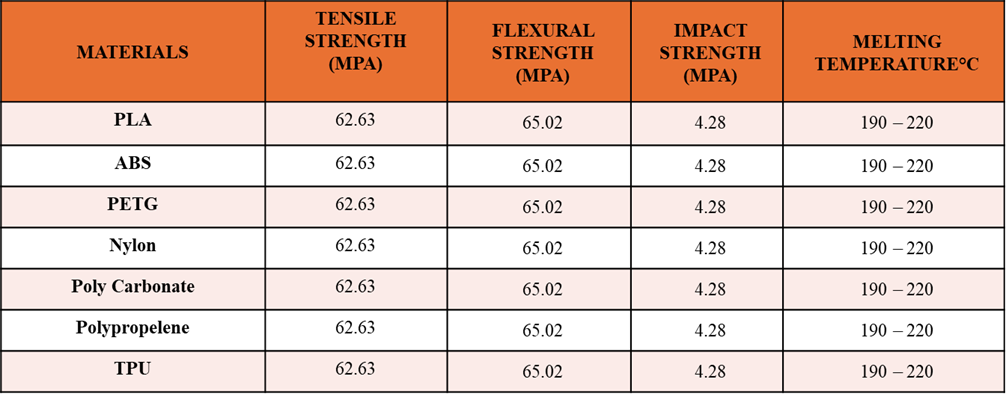

Additionally, SimIS' FDM solution offers large build volumes, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate. Our full list of plastic material capabilities is constantly being expanded and updated to fit your unique manufacturing needs.

Fused Deposition Modeling (FDM)

FDM technology can go about building quick prototypes with strength and speed, at a very economical price in a wide range of thermoplastic materials, which makes it a very attractive option.

How Fused Deposition Modeling Works

With FDM technology, a spool of the chosen feedstock is introduced to a typical fused deposition modeling system via an extruder, which regulates the feed movement of the polymer to the heater where it melts. This molten polymer is extruded through a nozzle and deposited onto the print bed, also known as the build platform. The extruder, heater, and nozzle are all contained in a printhead which is attached to a gantry above the flat build platform. This is designed to offer relatively high freedom of motion in the X and Y axes as the material is deposited.

Manufacturing on Demand!

FDM Applications

Concept Models

Concept Models

The speed and versatility of FDM lets engineers create physical snapshots of their designs.

Rapid Prototyping

Rapid Prototyping

An FDM machine can be used to create durable prototypes that withstand thermal, chemical, and mechanical stress.

Manufacturing Tools

Manufacturing Tools

High-performance materials make FDM ideal for producing jigs, fixtures, and production tooling.

Why Use FDM For Your Parts?

Fused deposition modeling (FDM) is among the most easily accessible and recognizable additive manufacturing technologies worldwide. Available to both 3D printing hobbyists and large-volume manufacturers alike, it is known for its speed and precision in generating three-dimensional polymeric structures using a choice of feedstock materials. The range of filaments available for fused deposition modeling include:

Acrylonitrile butadiene styrene (ABS-M30, ABS-M30i, ABSi)

Acrylonitrile styrene acrylate (ASA)

Polycarbonates (PC, PC-ABS and PC-ISO)

High-performance plastics (PPSF, Ultem 1010, Ultem 9085, and Nylon-12)

Benefits Of Fused Deposition Modeling

FDM printing is a cost-effective additive manufacturing process, especially for rapid prototyping or low-volume production. Since FDM prints require little post-processing and use more readily available materials, leads times from quote to print and delivery are fast.

Why Choose SimIS for FDM 3D Printing?

1. Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

2. Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.